- Home

- About Us

How Scissors are Manufactured?

About Stainless Steel

Product Material

Blade Processing

Screen/Pad/Heat Transfer Printing and Laser Marking

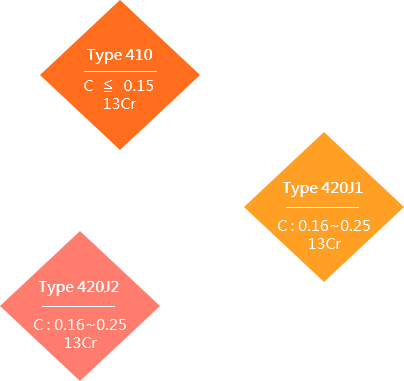

Stainless steel is a family of iron-based alloys that contain at least 10.5% chromium a composition that prevents the iron from rusting. Stainless steel's resistance to ferric oxide formation results from the presence of chromium in the alloy, which forms a passive film/layer that protects the underlying material from corrosion attack, and can self-heal in the presence of oxygen.

The steel will be harder with increase of carbon , but the steel will also be more brittlely and vulnerable to rust. Other elements such as Nickel and Molybdenum may be added to enhanced formability and increased corrosion resistance.

The steel will be harder with increase of carbon , but the steel will also be more brittlely and vulnerable to rust. Other elements such as Nickel and Molybdenum may be added to enhanced formability and increased corrosion resistance.

| Model | C | Si | Mn | P | S | Cr | Mo | V | N |

|---|---|---|---|---|---|---|---|---|---|

| SUS410 | ≦0.15 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 11.50~13.50 | — | — | — |

| SUS420J1 | 0.16~0.25 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 12.00~14.00 | — | — | — |

| SUS420J2 | 0.26~0.40 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 12.00~14.00 | — | — | — |

| EN1.4116 | 0.45~0.55 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 14.00~15.00 | 0.50~0.80 | 0.10~0.20 | — |

Product Material

Blade

The material of our scissors' blade is SUS 420J2 stainless steel, purchased from one of the world's leading producers of integrated steel - Japan JFE steel company(JFEスチール). After careful comparisons of varied brands of stainless steel in the market, we decide that the products of Japan JFE possess the steadiest quality, and are therefore the most reliable. Since we set “Providing The Best Quality” as our main goal, the stainless steel of the company becomes our choice for customers.

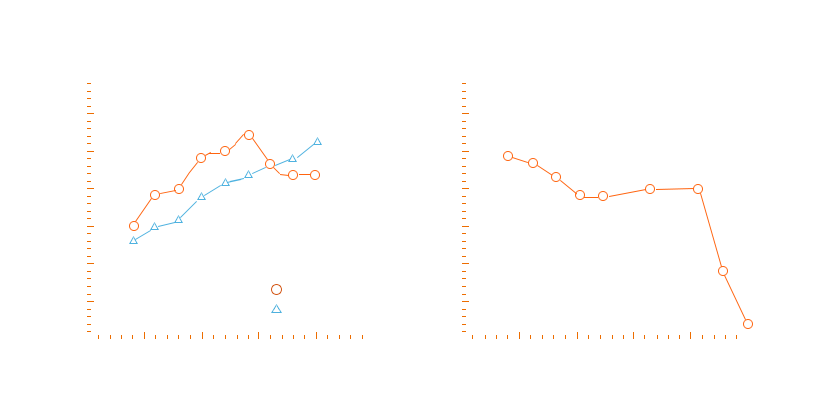

About 420J2

Stainless steel grade 420J2 is highly corrosion resistant. It has good corrosion resistance in mild atmosphere as well as domestic and industrial environments. It is also resistant to dilute nitric acid, carbonic acid, ammonia, crude oil, detergent solutions, vinegar, food acids, diverse petroleum products, and steam.

Stainless steel grade 420J2 is known for possessing good strength and reasonable impact resistance in hardened and tempered conditions when compared with 440 grades.

For more information, please visit

http://www.azom.com/article.aspx?ArticleID=9170

| Chemical Composition % | Mechanical Proerties | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mb | P | S | Cr | Tensile Test | Hardenss | Bend Test | |||||

| Yield Strength N/mm2 | Tensile Strength N/mm2 | Elongation % | HV | HRB | HBW | Bending Angle | Inside Radiust:Thickness | ||||||

| 0.26~-0.40 | 1.00↓ | 1.00↓ | 0.040↓ | 0.030↓ | 12.00~14.00↓ | 255↑ | 540↑ | 18↑ | 247↑ | 99↑ | 235↑ | --- | --- |

About 4116

A high-hardness martensitic stainless steel with improved corrosion and wear resistance (edge toughness) compared to 420J2.

It is usually used for hygienic applications and food processing which make it a superb material for kitchen scissors. But the material cost is also much higher than 420J2.

Handle

Since we set "Providing The Best Quality" as our main goal, we need to give our customer a strong handle that can support their work. We only use first time raw material to make the handle, the recycled-material do not meet our standard. We choose DSM Novamid(former Mitsubishi's Novamid ), Radipol and TEKNOR APEX(former DSM)as our nylon and TPV supplier. Our handle main material is the compound of PA66 and PA6, it has the strength of PA66 and the surface quality of PA6.

Blade Processing

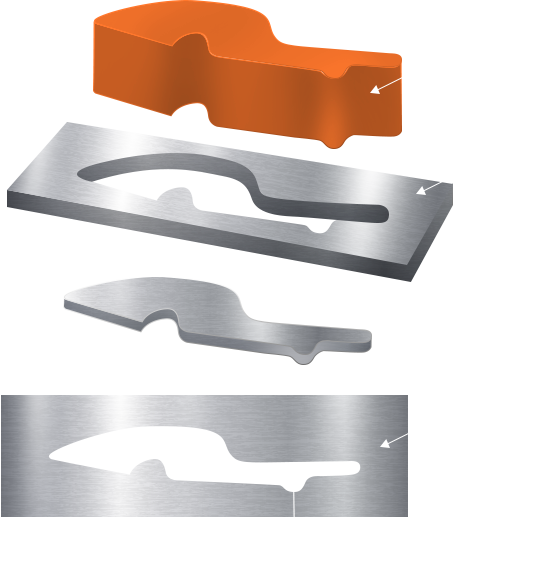

STEP 1

Place flat sheet metal in either blank or coil form into a stamping press machine where die blank the metal into the form of a scissors’ blade.

By using fineblanking (Advance blanking method), the blades’ edges will be smoother than traditional blanking, but the cost is also higher.

STEP 2

Heat treatment is a metalworking processes used to alter the physical properties of the steel.

The hardening process makes the steel harder so it can resist cutting abrasion.

Tempering is performed after hardening, which is used to increase the toughness.

Cooling the hardened steel slowly will produce a steel hard but less brittle.

STEP 3

Grinding/ Polishing / Sharpening / Serrating /Creating Notch

These process are done by using grinding wheel and sand belt, these steps are all about removing of the metal.

Grinding process remove the metal part in big quantity(0.1~0.15mm) ,which sand belt polishes remove metal just a little bit(around 0.01mm). Grinding can remove metals dents where polishing makes the blades surface bright,shiny and harder to get rusty .

The sharpening process produces the cutting angle/edge, different angle/edge are for different cutting applications.

Serrating creates many small teeth on the edge of the blade, the serration will bite the work piece to prevent work piece slipping.

The Notches on the blade are used to hold the work piece inside and also reduce the opening angle of scissors. According to the lever principle, placing the work piece closer to scissors’ axis allows you to use less force to cut the hard wide cables , that’s why the notch is always close to the axis.

screen/pad/

heat transfer printing and laser marking

You can put your Logo or item number on the plastic part by screen/pad/heat transfer printing or laser mark it on the blade.

Laser Marking (laser engraving) , is a method which use laser light to mark pictures or words on materials.

Screen printing is a printing technique where a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil.

Pad printing (also called tampography) is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate.